Guidance on Printing Zines from a Single Business Owner

Making a zine, a small-circulation self-published work, can be an exciting venture for creators. To ensure a successful and professional-looking end product, it's essential to consider various factors in the printing process. This article will delve into three key areas: binding options, finishing techniques, and cost-saving strategies.

Binding Options

When it comes to binding, there are several choices available, each with its unique advantages and drawbacks. Saddle stitch, a popular and cost-effective option, staples sheets through a folded center, giving a classic booklet feel. Perfect binding, with a glued spine, offers a professional, paperback book look and is suitable for longer zines or those seeking a polished finish. Spiral or wire-o binding allows the zine to lay flat, making it a good choice for usability, although it may appear less traditional. Case bound (hardcover) with sewn signatures is the most durable and premium option, but it is costly and typically reserved for high-end zines or books.

Finishing Techniques

The physical construction of a zine is significantly impacted by finishing, which includes cutting, folding, and binding. Many professional printers include finishing in their services, but DIY finishing (hand-binding or using local studios with print finishing facilities) can provide more artistic control and cost savings, albeit requiring test dummies to be made first to avoid waste. Control over finishing can enhance project integrity and aesthetic, but it can be time-consuming for larger print runs.

Cost-Saving Strategies

Several strategies can help keep costs manageable while maintaining a professional look for your zine. DIY finishing to reduce printer fees is one such strategy, provided that time and skill are available. Prototyping and test runs with scrap paper are crucial for avoiding costly mistakes in final binding or cutting. Choosing simpler binding like saddle stitch for shorter zines can also help keep costs lower. Additionally, selecting printers that offer competitive pricing, low minimum orders, and easy online ordering with instant quotes and file checks can help save costs. Lastly, using standard paper sizes and paper stocks, such as matte or uncoated, balances quality and price.

In conclusion, careful decision-making at the outset regarding binding significantly influences layout and printing methods. The choice of finishing approaches depends on desired quality, time, and budget. Employing prototyping and some DIY finishing can help keep costs manageable and produce a professional-looking zine. The process of zine making, with its DIY approach to giving ideas physical form and distributing them directly, carries a subversive quality inherent to it.

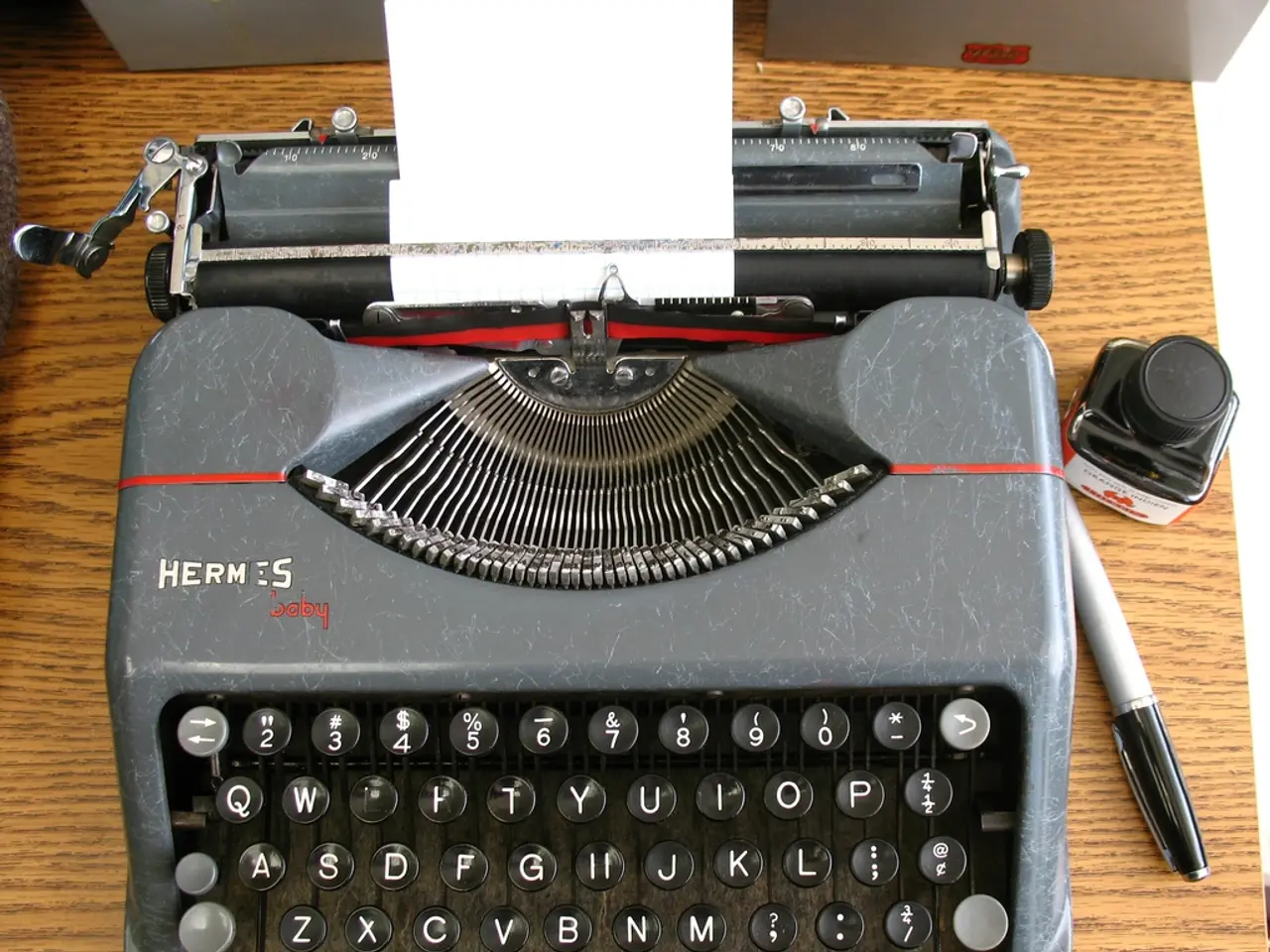

The DIY approach can extend beyond the content creation of a zine, as one might opt for DIY finishing techniques to enhance artistic control and potentially save costs. In the realm of home-and-garden projects, upcycling old hardware can create an unique and personal touch when binding a zine, reflecting the lifestyle of the creator.